The Situation: A company producing specialty metal products had been monitoring the pressure levels of its hydraulic pump room using glycerin-filled gauges. This system required a worker to manually check the gauges once at the beginning, and once at the end of each of the facility’s three shifts.

Standard pressure gauges have downsides. The dial doesn’t allow for exact pressure levels and the gauges do not account for the level trends between the times that the gauges are being checked.

Therefore, sudden drops or spikes in pressure go unnoticed, and can have disastrous effects on the customer’s equipment, from overheating and equipment inefficiency, to eventual breakdown. The customer needed a solution that allowed workers to check the pressure levels of the hydraulic pumps more efficiently, but also track and trend the levels throughout the day.

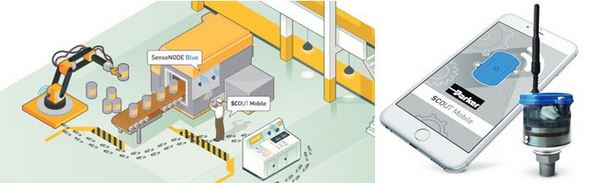

The Solution: The customer purchased and installed SensoNODE™ Blue sensors on the hydraulic pumps and used SCOUT™ Mobile software installed on workers’ mobile phones. The system has allowed workers to track and trend data that had previously been lost, catching all of the sudden fluctuations typically gone unnoticed. Monitoring is also a simpler process, allowing workers to download readings and email the information to the next shift.

Customer’s Feedback:

- Tracking & trending of data allows our workers to quickly address any issues before they escalate

- Workers can easily install & wirelessly gather readings from the hydraulic pump room

- Information gathered with the SCOUT mobile software can be emailed and downloaded to the next shift, which makes it easier to share more accurate information

- When used with Scout Mobile, alarms warn us of dramatic pressure drops or spikes