RECENT POSTS

Archives

We are excited to announce a full line-up of training and development courses for the 1st quarter! Training is free and offered from 1:00pm-2:30pm. Don’t miss our new Transair Aluminum Piping class offered in March at all training facilities.

Ann Arbor Class Offerings

Thursday, March 14th @ 1:00-2:30pm

Industrial Lubrication Practices – Register Here

Moving parts on your machinery & equipment require proper lubrication to maximize uptime and ensure long life. We’ll discuss several lubrication concepts and the available equipment needed to provide just the right amount of lubrication.

Thursday, March 28th @ 1:00-2:30pm

Basics of Hydraulic Filtration for Greater Machine Up-time – Register Here

Proper filtration during use is critical to avoid costly contamination problems and will maximize your machine’s up-time. This informative class will filter out any confusion about how to keep your hydraulic systems clean and functioning properly.

Thursday, March 21st @ 1:00-2:30pm

Transair Aluminum Piping for Compressed Air, Vacuum and Inert Gas Applications – Register Here

Transair’s lightweight components and quick-connect interlocking design allow for easy and immediate layout modifications and require no need to thread, solder, or glue pipe. In this course, we will cover the how to properly size your system, the differences between aluminum and black pipe and potential cost savings.

Farmington Class Offerings

Thursday, February 14th @ 1:00-2:30pm

Cylinder Sizing Fundamentals – Register Here

Choosing the correct cylinder is key to your motion-control solution. In this session we will cover basic terminology & sizing formulas, cylinder types and their applications, how to identify misapplications and more.

Thursday, March 7th @ 1:00-2:30pm

Alternative Fuel Conversion Basics – Register Here

Why natural gas? Fleet Managers across the world have made the switch from gasoline to CNG / LPG to lower costs and increase efficiencies. This course will focus on the components required for conversion, government incentives and focused case studies.

Wednesday, March 20th @ 1:00-2:30pm

Transair Aluminum Piping for Compressed Air, Vacuum and Inert Gas Applications – Register Here

Transair’s lightweight components and quick-connect interlocking design allow for easy and immediate layout modifications and require no need to thread, solder, or glue pipe. In this course, we will cover the how to properly size your system, the differences between aluminum and black pipe and potential cost savings.

Shelby Class Offerings

Thursday, January 31st @ 1:00-2:30pm

Hydraulic Accumulators: What are They & How Do They Work? – Register Here

Accumulators regulate the performance of a hydraulic system by providing an additional volume of system fluid, pressurized by an external gas supply. For industrial applications, there are three types of hydro-pneumatic accumulators: piston, bladder and diaphragm. We’ll help you understand each type so you can choose the best solution for your system.

Thursday, February 7th @ 1:00-2:30pm

Hose Assembly & Crimping Techniques – Register Here

Not all Hoses are created equal and, more importantly, not all Crimps are the same. Safety is first priority and we will teach you how to properly inspect a hose assembly to make sure you have what you need to keep your people safe and your equipment running without leaks.

Thursday, February 28th @ 1:00-2:30pm

Thread ID & Safety Works – Register Here

Identifying thread types in industrial applications can be very confusing. This class will show you how to identify SAE, NPT, Metric & BSP thread types and will discuss hydraulic systems best safety practices.

Tuesday, March 19th @ 1:00-2:30pm – Register Here

Transair Aluminum Piping for Compressed Air, Vacuum and Inert Gas Applications

Transair’s lightweight components and quick-connect interlocking design allow for easy and immediate layout modifications and require no need to thread, solder, or glue pipe. In this course, we will cover the how to properly size your system, the differences between aluminum and black pipe and potential cost savings.

Lansing Class Offerings

Thursday, February 21st @ 1:00-2:30pm

Pneumatic Valve Application and Communication Protocols – Register Here

Pneumatic technology has progressed tremendously in the past several years. We will walk you through the various protocol options and teach you how to choose the right (not always the newest) interface and valves for your machine!

Friday, March 22nd @ 1:00-2:30pm

Transair Aluminum Piping for Compressed Air, Vacuum and Inert Gas Applications – Register Here

Transair’s lightweight components and quick-connect interlocking design allow for easy and immediate layout

modifications and require no need to thread, solder, or glue pipe. In this course, we will cover the how to properly size your system, the differences between aluminum and black pipe and potential cost savings.

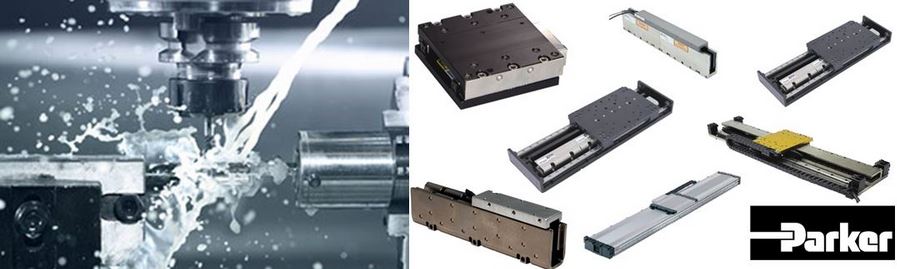

Parker’s Virtual Engineer is an innovative design tool for linear motion applications in automation. Save engineering time in three simple steps:

- Enter application details using the intuitive interface

- Size and select products that meet the demands of your application

- Get a quote, share your project, and download files easily

You expect the best from your machinery, and maintaining engine oil is key to maximizing the productive life of equipment. Changing oil sounds simple, but we know the process can be complicated, messy and dangerous.

Fast. Clean. Safe.

Parker’s new QuickFit Oil Change System is a complete oil change system that revolutionizes the process with a faster, cleaner and safer way to change oil in engines and machines. In three easy steps, purge, extract and refill your system with new oil without ever spilling a drop. Click here to learn more.

Enerpac’s new lock-grip pullers provide a simple, safe and cost-effective way to remove shaft-mounted parts. Both mechanical and hydraulic pullers are offered to suit your application requirements.

Key Features:

- Convenient adjustment handle simplifies the position of jaws on application and increases speed of operation

- Locking mechanism helps prevent jaws from slipping off application while pulling

- Greater spreading width on jaws enables use on thicker objects

- Spindle protector helps prevent damage to spindle when pulling against a flat surface

There is no better time than the holidays to express our appreciation for your business! We wish you and your family a happy and joyous holiday season and extend our sincere thanks for your support this year.

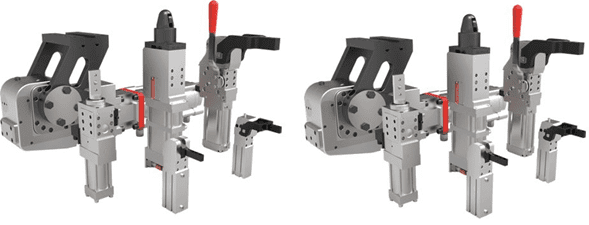

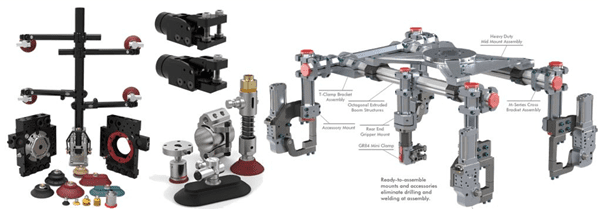

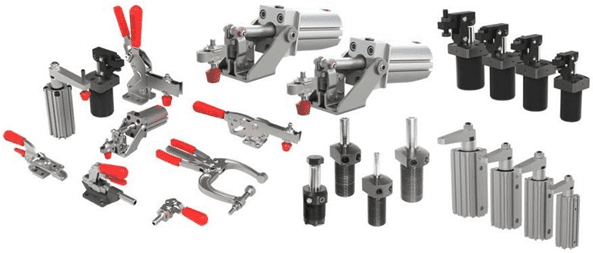

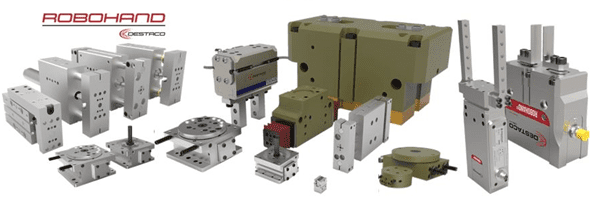

DESTACO’s Pneumatic Power Clamps range from heavy-duty sealed clamps for welding environments to compact light-duty clamps for a variety of clamping, gripping applications. Pin clamps and pivot units are used in locating and positioning applications. All of these products offer exceptional clamping forces, holding capacities and durability.

DESTACO end effectors are designed to help you move parts faster in today’s production line by using high strength, lightweight aluminum modular components, durable vacuum cups and the fastest venturis on the market.

DESTACO manual and pneumatic light-duty clamps are built to last for years of service and designed to keep your work pieces in place. Manual and light-duty clamps are offered in a variety of styles to hold a part securely in place during an application.

Since 1980 with the release of its patented series of parallel grippers, the Robohand name has come to represent the best in innovation, quality and reliability.

Gripping Solutions Include:

- Standard & Precision Pneumatic Grippers

- Maintenance-Free Electric Grippers

- Clean Room, Food and Automotive Grippers

- High Quality Linear Actuators (Slides)

- Full line of Pneumatic Rotary Actuators (Rotaries)

- Automatic Full-Sensing Robotic Arm Tool Changers

We are proud to announce we are now an authorized DESTACO distributor! You can now count on Sidener Engineering for high performance DESTACO Robohand grippers, rotaries, slides, manual & pneumatic clamps and end effector solutions.

DESTACO is considered the worldwide leader in the design, manufacturing and support of clamping, gripping, transferring and robotic tooling solutions for workplace and flexible automation needs. The company offers a vast range of industrial robotic gripping solutions for precise parts handling and pick and place capabilities.

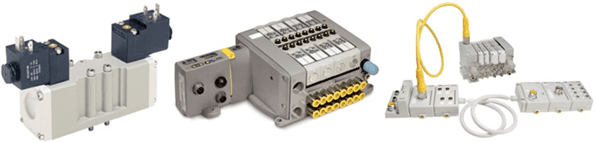

Pneumatic valves have come a long way since the development of the compressor more than a century ago and it can be a real challenge to ensure you’re taking full advantage of the latest development for your organization. Here are three ways to adopt the latest advances in pneumatic valve technology…

- Choose components that adhere to ISO valve standards

ISO International Standards ensure that products are safe, reliable and of good quality, helping to deliver increased customer satisfaction through consistent quality. ISO standards can also be used strategically by businesses to help reduce costs through improved systems and processes, minimize waste and increase productivity. - Opt for intelligent and simple wiring solutions

Utilizing collective wiring solutions provides and elegant mechanism to consolidate solenoid wiring into a single “collective” connection on the valve manifold. This method significantly reduces costs and complexity, as the valve can be moved out of the control cabinet to the point-of-use application located near the pneumatic process, eliminating long tubing runs and delayed responses in operation. - Incorporate cloud-connected innovations

Incorporating a fieldbus solutions to control pneumatic valves could be the first step towards implementing intelligent, cloud-connected industry 4.0 innovations on the assembly line. These solutions create an automated industrial network, specifically designed for communications between programmable logic controls (PLCs) via a communications system such as Ethernet.

With the onset of Industry 4.0, factory and production environments are adopting industrial networks to become more connected and intelligent. Adding intelligence to machines gives the opportunity to implement a predictive maintenance strategy – the ability to foresee issues and plan rather than to react to maintenance needs.

Lincoln and SKF Automatic Lube Systems

Manual lubrication typically produces inconsistent lubrication which leads to wasted lubricant and allows contaminants to enter the bearing – producing premature wear. Consistent lubrication (small, precise amounts applied frequently) extends

Parker 09 Series Motor Product Obsolescence

Parker streamlined their product offering and discontinued the 09 Series Hydraulic Motor. These products include the following prefixes: 09A-, 09S-,09SP-. Contact us for alternative product solutions.

Exotic Automation Appointed Distributor for SKF & Lincoln Lubrication Products

The new partnership will expand Exotic Automation & Supply’s lubrication product offering. December 12, 2017 – Farmington Hills, MI: Exotic Automation & Supply, a leading manufacturer and distributor of automation

Exotic is now an SKF / Lincoln Distributor!

Have you heard? Exotic Automation & Supply is now an authorized distributor for SKF and Lincoln lubrication products. The SKF name is widely-known for providing the most complete portfolio of

Parker Transair Advanced Pipe Solutions

Fast, flexible, and easily modified, Transair is the ideal aluminum pipe system for compressed air, vacuum, and inert gas applications. Durable and corrosion-resistant, Transair’s lightweight construction outperforms traditional piping systems.

Parker Adds 187 Hose to the GlobalCore Family

Parker’s Hose Products Division announced the launch of 187 hose to the GlobalCore family. The 187 Hose provides 1,000 psi constant working pressure, is available in sizes -16 through -48

Need a Hose or Fitting? Let Hose Finder Help!

Just Register, Download & Go! Parker’s HoseFinder mobile device application allows you to search the entire catalog of products from Parker’s HPD, IHP and PFD Divisions quickly and efficiently. Narrow

Meet our Fluid Connector Business Unit Manager!

Mike Chapman is Exotic Automation & Supply’s Fluid Connector Business Unit Manager. Mike works as a liaison between Exotic’s Account Managers and Parker Hannifin’s Fluid Connector Divisions to provide customers

Motion & Control Insider Monthly – Answers

Monthly Brain Teaser Answers: November Answer: October:

Trainings for the 4th Quarter!

New Training Locations! We have extended our training & development schedule to now offer courses at 4 of our locations – Ann Arbor, Farmington, Lansing & Shelby Township! Classes are

Please Visit us at our Shelby Open House!

Please join us as we celebrate the opening of our Bent Tube Assembly Facility at our Shelby Township branch! Our customer’s demand for bent tube assemblies has grown over the

Linear Motor Solutions from Parker Electromechanical

What is a linear motor? At its core, a linear motor is a rotary motor that has been unwound and laid out flat. It allows for coupling of the motor