Farmington Hills, MI (PRWEB) December 2, 2012 – Exotic Automation and Supply’s Alternative Fuels Product Group has successfully completed the Canadian Standards Association’s (CSA) certification process for manufacturing and assembling compressed natural gas (CNG) high-pressure hose assemblies.

The CSA certification is relied on by NGVAmerica members for standards relating to the conversion of gasoline and diesel powered vehicles and other mobile equipment types to CNG or LPG platforms. Exotic Automation and Supply is ISO 9001:2008 certified and features full in-house testing capabilities.

“Every CNG hose assembly is fully tested and certified,” said Henry Testa, Sales Director for Exotic’s Alternative Fuels Product Group. “Our hoses go through extensive OHMS testing, static pressure testing, and electrical conductivity validation. The procedure assures each component passes pressure tests 2X above operating pressure.”

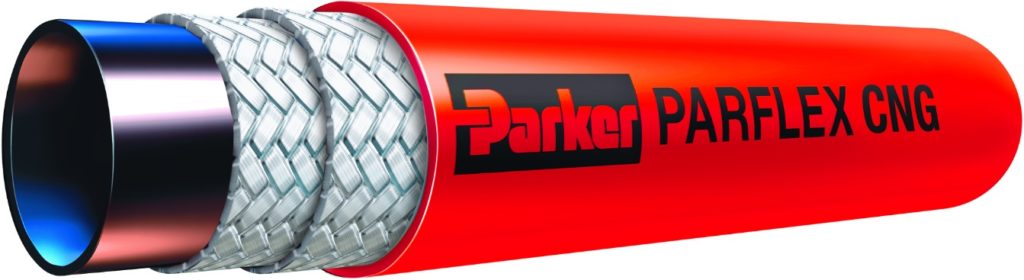

Exotic Automation and Supply’s high pressure CNG hose assemblies conform to NFPA 52, ANSI/IAS NGV 4.2-1999, and CSA 12.52-M99 standards. The CNG hoses have a working pressure of up to 5,000 psi and operate in temperatures from -40oC to 180oF. Their proprietary polyurethane jacket allows maximum flexibility, durability, abrasion resistance and protection from outdoor elements such as ultraviolet light.

Exotic’s low pressure LPG hose assemblies are rated up to 425 psi and conform to ECE R110/R67, UL21, 588 569 & ECE 110 Class 1/UL Standards. The LP hose operates in a temperature range from -40oC to 250oF and exceeds the Canadian Gas Association specification CAN / CGA-8.1-M86 Type lll, which means it meets permeation requirements of 1,6 g/m2 per day.

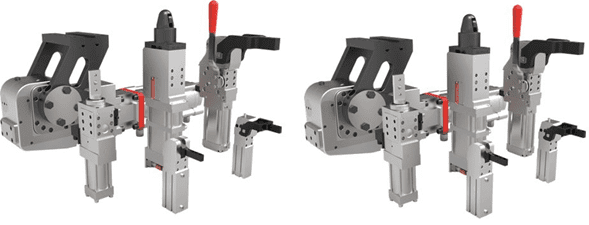

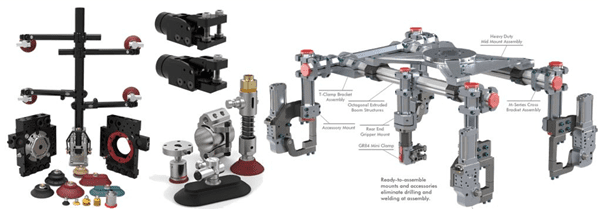

Exotic’s Alternative Fuels Products Group also provides on-board components ranging from receptacles (NGV1 Profile, filtered and non-filtered), check valves, ball valves, coalescers, filters, nozzles, high and low pressure lock-off solenoid valves and O-Ring (Seal-Lok™) fittings.

As the total number of alternative fuel vehicles and mobile equipment expands, the need for dispensing components has increased as well. Exotic Automation provides certified dispensing hose assemblies, dispensing nozzles, and dispensing finite filters.

“With the CSA certification for compressed natural gas hoses, along with our liquefied petroleum gas hoses and component offerings, we now serve as a single-source solution for any business or organization involved in converting gasoline and diesel vehicles to CNG and LPG,” said Steve Orlando, Vice President of Sales and Marketing for Exotic Automation and Supply.

“In addition to our on-board CNG and LPG components, our alternative fuel dispensing offerings make Exotic Automation & Supply among the most comprehensive alternative fuels product providers in the industry.”

About Exotic Automation & Supply: Exotic Automation & Supply’s headquarters is located in Farmington Hills, Michigan. The company maintains full service centers throughout Michigan with locations in Freeland (Saginaw), Lansing, Taylor, Flint, Jackson, Rochester Hills, as well as at the main Farmington Hills complex. The company employs approximately 150 people and saw sales exceeding $50 million in 2011.