Our nine (9) Michigan ParkerStores are just right around the corner when you need them the most. Stop by Exotic for hydraulic hose assemblies, quick disconnects, fittings, adapters and everything to keep your machines and snow removal equipment running. Find a location near you here.

Search Results: Day: January 20, 2017

RECENT POSTS

RECENT COMMENTS

Archives

Categories

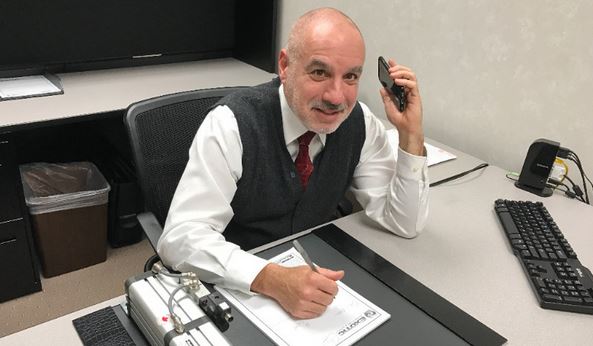

Henry Testa is the Director of Sales for Exotic Automation’s Southeast Michigan region. His team is responsible for all served Exotic markets – automotive MRO, machine tool, defense, steel, chemical and industrial accounts. Henry’s sales team delivers value to our key customers. Value enablers include inventory management based on Exotic’s 10 million dollar local inventory, technical application support in hydraulics, pneumatics, work holding, fluid connector, lubrication, gasket & sealing and molded rubber and plastics. Henry has 12 local account managers who are trained in these products and is also supported by product managers that help our customers increase their productivity and improve their profitability.

The Situation: A company producing specialty metal products had been monitoring the pressure levels of its hydraulic pump room using glycerin-filled gauges. This system required a worker to manually check the gauges once at the beginning, and once at the end of each of the facility’s three shifts.

Standard pressure gauges have downsides. The dial doesn’t allow for exact pressure levels and the gauges do not account for the level trends between the times that the gauges are being checked.

Therefore, sudden drops or spikes in pressure go unnoticed, and can have disastrous effects on the customer’s equipment, from overheating and equipment inefficiency, to eventual breakdown. The customer needed a solution that allowed workers to check the pressure levels of the hydraulic pumps more efficiently, but also track and trend the levels throughout the day.

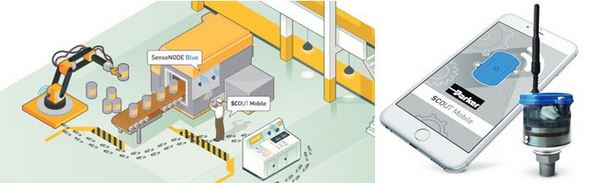

The Solution: The customer purchased and installed SensoNODE™ Blue sensors on the hydraulic pumps and used SCOUT™ Mobile software installed on workers’ mobile phones. The system has allowed workers to track and trend data that had previously been lost, catching all of the sudden fluctuations typically gone unnoticed. Monitoring is also a simpler process, allowing workers to download readings and email the information to the next shift.

Customer’s Feedback:

- Tracking & trending of data allows our workers to quickly address any issues before they escalate

- Workers can easily install & wirelessly gather readings from the hydraulic pump room

- Information gathered with the SCOUT mobile software can be emailed and downloaded to the next shift, which makes it easier to share more accurate information

- When used with Scout Mobile, alarms warn us of dramatic pressure drops or spikes

The heavy industrial shock absorber from ACE tops off the company’s offerings in damping technology. This ACE category gives designers a choice between self-compensating and adjustable machine elements. Whichever design is chosen, this type of shock absorber impresses with its robustness and operational readiness wherever heavy loads need to be reliably stopped on-the-spot and at a precise point. Learn more here

Register Now for The 2021 Motion & Control Summit!

January 12, 2021

The first annual 2021 Virtual Motion & Control Summit will be held February 17-18th, 2021. The 2-day event is free to attend and full of motion & control, industrial hydraulics, fluid power

A Look Back – 2020 Highlights

December 18, 2020

In January 2020, we relocated our Headquarters to a brand new facility in New Hudson, MI. The location off I-96 provides quick access for customers and direct routes to

It’s Coming February 2021 – RSVP Today!

December 18, 2020

The first annual 2021 Virtual Motion & Control Summit will be held February 17-18th, 2021. The 2-day event will be full of motion & control, industrial hydraulics, fluid power safety

Happy Holidays!

December 18, 2020

In warm appreciation of our association during the past year we extend our very best wishes for a happy holiday season!

Follow us on Social Media for Your Chance to Win $50!

November 4, 2020

Congratulations to this month’s winner, Heather Veldman! Want to win a $50 American Express gift card? We’re giving away one each month for the rest of the year! Just follow us

New Enerpac Hydraulic Post Tensioning Pumps

November 4, 2020

Staying on time and under budget is critical for both residential and commercial concrete work. Reducing the time spent per tendon is key to achieving both goals. Specifically designed for

Faster, Cleaner & Safer Oil Changes

November 4, 2020

Cleaner and safer oil changes in just 30 minutes! Parker Hannifin’s QuickFit Oil Change System revolutionizes the process with a faster, cleaner and safer way to change engine oil. In three easy

Futuristic Auto Show Project Requires ACE Gas Springs

November 4, 2020

An automotive engineering firm was tasked to redesign an SUV into a futuristic concept for the annual automotive show. Gull wing doors were part of the concept which required 2

Register Now for Next Week’s Webinar!

November 4, 2020

*New* Sizing Electromechanical Cylinders for Retrofit Applications Webinar Join us for an all new webinar, Sizing Electromechanical Cylinders for Retrofit Applications, on Thursday, November 12th at 10:00am. In this webinar,

Stop by our ParkerStores for Assistance Today!

November 4, 2020

All 12 of our ParkerStores are open to assist you Monday through Friday from 8:00am to 5:00pm. We’re here to help provide you with custom made hose assemblies, in-stock hydraulic

Transair and Filtration Solutions Featured in the New Chevy Commercial!

October 20, 2020

Check out Exotic’s Transair Aluminum Piping and Filtration solutions displayed in the new Chevy commercial! https://www.youtube.com/watch?v=cm5YTAfXrVk

Follow us on Social Media for Your Chance to Win $50!

October 13, 2020

Congratulations to this month’s winner, Stephanie Schummer! Want to win a $50 American Express gift card? We’re giving away one each month for the rest of the year! Just follow us