Parker Hannifin’s Miniature Precision Rotary (mPR) stage is designed to meet the needs of OEMs and machine builders seeking very high precision in a compact direct drive product. High angular resolution and precision angular repeatability, combined with high precision runout values, make the mPR a high performer in the field of precision rotary motion control.

Learn more about the mPR Rotary Stage here.

Search Results: Day: January 23, 2018

RECENT POSTS

RECENT COMMENTS

Archives

Categories

Enerpac’s new Low-Height Skidding System is a modular system that can jack and slide heavy loads over a pre-constructed track. The system is comprised of a series of skid beams moved by hydraulic push-pull units, traveling over a pre-constructed track. A series of special PTFE-coated pads are placed on the skid tracks to reduce friction. The push-pull units are powered by a standard Enerpac Split Flow Pump to ensure each skid beam travels synchronously.

In addition to its low height, this system offers a 2-in-1 design. It can be used either on a fully supported surface or combined with the optional track support for added rigidity when the support surface is not fully supported or when spanning a gap is necessary. This two-part design means you do not need to own two sets of track for various ground support conditions.

Features:

• 2-in-1 track design for added support

• Intuitive pump controls

• Easily reversible to change skidding direction

• Portable design for quick setup

• 400 ton skidding capacity with two push-pull units

|

Don’t Forget to Register for Free Training Classes!

October 18, 2018

Don’t forget to register now for 4th quarter training & development classes! Training is free and offered every Thursday from 1:00-2:30pm. Click here to view the course syllabus and register

Exotic Automation & Supply to Exhibit at the 2018 Die Casting Congress & Exposition

October 2, 2018

Exotic’s solutions for die casting, including sand de-coring hammers, hydraulic safety valves, safety light curtains and safety mats will be showcased. October 2nd, 2018 – Farmington Hills, MI – Exotic

Register for Free Training & Development Classes

September 12, 2018

Registration for our 4th quarter training & development courses is now open! Training is free and offered every Thursday from 1:00-2:30pm. Space is limited so please register today by emailing

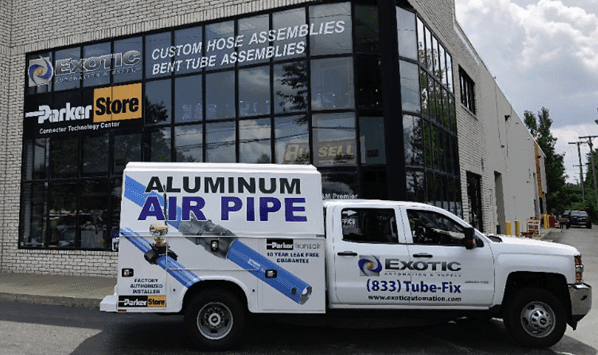

New! 24/7 Mobile Aluminum Pipe Installation Van

September 12, 2018

Exotic Automation & Supply is proud to launch a new mobile service vehicle to our Retail / Service Team. The new 24/7 Transair Aluminum Pipe Installation Truck comes to your

Parker’s SCOUT Software is now Voice of the Machine™ Software

September 12, 2018

Parker Scout Mobile is now Voice of the Machine. The Voice of the Machine Software works with SensoNODE™ Sensors to wirelessly monitor assets without interrupting production. Ideal for large-scale operations

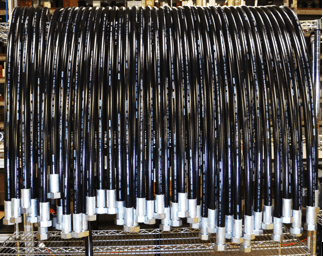

How to Properly Measure a Hose Before Crimping

September 12, 2018

In this 3-minute video, you will learn how to properly measure your hose assembly prior to making the first cut.

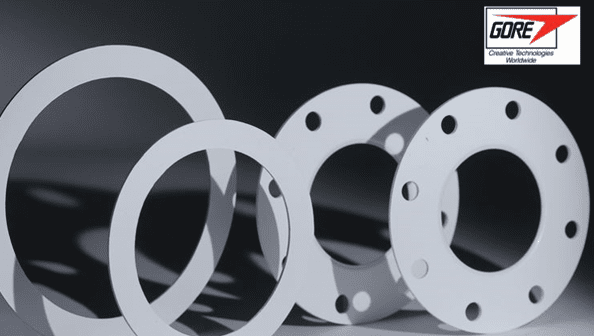

Gore Sealants for Industrial Applications

September 12, 2018

When a reliable seal is needed in challenging situations – including exposure to high pressures and temperatures, abrasion, imperfect flange surfaces and harmful chemicals – Gore provides reliable sealing solutions.

New Enerpac High Performance Battery Powered Pump

September 12, 2018

The ZC-Series cordless hydraulic pump is ideal for jobs that require a combination of portability, speed and safety and works well for remote locations without access to power and indoors

Visit us at the 2018 Die Casting Congress & Expo!

August 16, 2018

Exotic Automation & Supply will be exhibiting at the 2018 Die Casting Congress & Expo, October 15-17, 2018 at the Indiana Convention Center. On display will be our Control Reliable

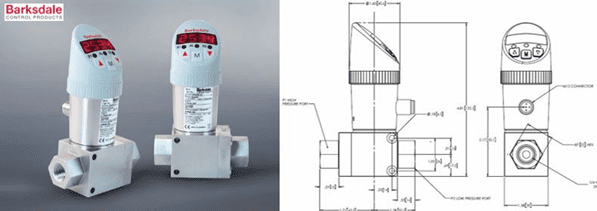

Barksdale Electronic Dual Differential Pressure Switch

August 16, 2018

Barksdale’s Electronic Dual Differential Pressure Switch is a differential switch, transmitter and gauge all in one! It’s features make it ideal for filtration systems, pump & compressor monitoring, fluid leak

Enerpac Low-Height Skidding System

August 16, 2018

Enerpac’s new Low-Height Skidding System is a modular system that can jack and slide heavy loads over a pre-constructed track. A series of special PTFE-coated pads are placed on the

Parker Twinhammer Dual Air/Water Hose

August 16, 2018

Parker Twinhammer hose was launched in response to an OSHA mandate and new rule to curb the amount of occupancy respirable crystalline silica (RCS) dust. The hose consists of bonded