Exotic’s unique safety solution offering, including hydraulic safety valves and de-coring hammers will be on display.

March 13th, 2018 – Farmington Hills, MI – Exotic Automation & Supply, a premier Parker Hannifin distributor, announced today they will be exhibiting at the 2018 Metalcasting Congress held at the Fort Worth Convention Center in Fort Worth Texas, April 3-5, 2018.

The 122nd Metalcasting Congress, sponsored by the American Foundry Society (AFS), is North America’s largest annual event for the metal casting Industry. The show combines an exhibition of over 200 industry suppliers and over 100 presentations from metal casting experts around the world. Topics cover all facets of metal casting, including shop-floor production to management tactics to the latest research advancements.

Located at booth #235, Exotic’s Safety Experts will be on-site displaying their line of Control Reliable Hydraulic Safety Valves and OMLER De-Coring Hammers emphasizing their Omler repair capabilities, and safety solutions for the foundry and die casting markets.

The company is an exclusive distributor and repair center for OMLER sand de-coring hammers. Application assistance along with in-stock inventory and repairs are provided from the company’s Noblesville, Indiana location.

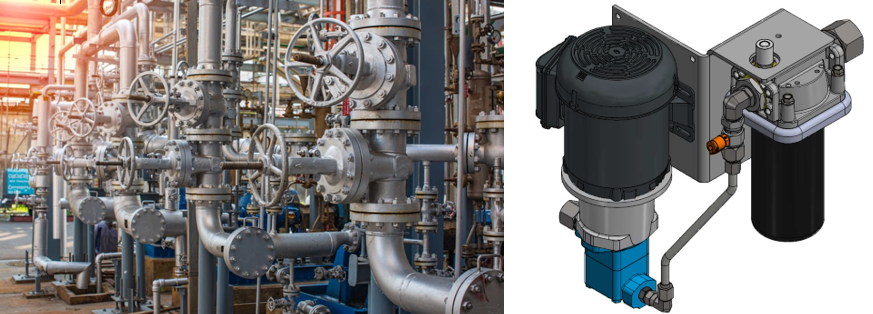

The company’s Control Reliable Hydraulic Safety Valve has become a product of increasing interest, as companies update and upgrade the safety systems of their hydraulic systems to include redundant valving and monitoring.

“Wherever hydraulic safety is a concern, our control reliable hydraulic safety valves are used.” Doug Webster, Product Manager said. “We see them most commonly used in applications such as hydraulic presses, rubber molding, coil slitting lines, paper processing and metal forming.”

“Safety is one of the most important concerns to businesses.” Steve Orlando, Vice President of Sales & Marketing said. “We are proud to offer an extensive portfolio of safety solutions to customers across the United States.”

Further information regarding the company’s safety line can be found on their website, www.exoticautomation.com/safety.

About Exotic Automation & Supply: Exotic Automation & Supply’s headquarters is located in Farmington Hills, Michigan. The company maintains full service centers throughout Michigan & Indiana with locations in Freeland (Saginaw), Lansing, Taylor, Flint, Jackson, Noblesville, Rochester Hills, Shelby Township as well as at the main Farmington Hills complex.