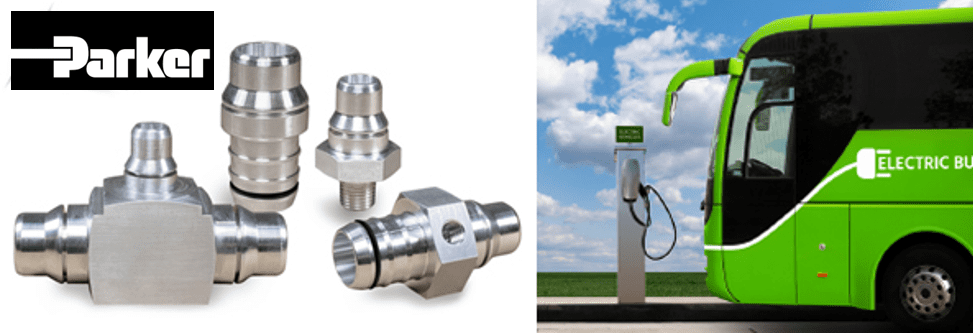

The new agreement authorizes Exotic to sell the aluminum piping in sizes 16.5mm to 168mm.

Farmington Hills, MI – April 3rd, 2018: Exotic Automation & Supply, a premier Parker Hannifin distributor, announced today they are now a full-line authorized distributor for Parker Transair piping in sizes up to 168mm. The new offering significantly expands Exotic’s ability to provide safe, lightweight, corrosion resistant piping solutions to customers.

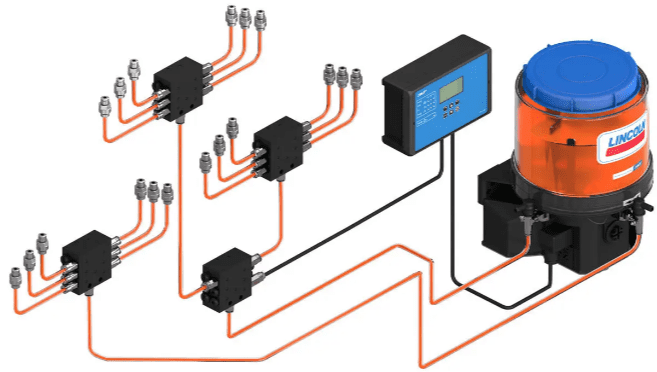

Parker Hannifin Transair is an aluminum pipe system for compressed air, vacuum and inert gas applications. Its lightweight components and quick-connect interlocking design allow for easy and immediate layout modifications and require no need to thread, solder, or glue pipe. Transair’s ability to integrate into existing copper and steel piping systems without compromising performance makes it ideal for upgrades or expansion products.

“A full-bore aluminum air piping system is a cleaner, safer, more cost-effective choice than traditional black iron pipe.” Mike Chapman, Business Unit Manager said. “It is 100% recyclable, 100% silicone free and does not contaminate customers air systems like traditional piping systems.”

Transair is also ideal for aggressive environments, with a powder-coated outer surface that enhances its mechanical, physical, and chemical properties. The product is also environmentally sustainable, responsible for reducing the carbon footprint over 80% versus steel piping installations.

“Our customers are requesting Transair systems more and more with the cost savings they provide compared to other piping systems.” Steve Orlando, Vice President of Sales & Marketing said. “We have significantly increased our stock in sizes up to 168mm at all 10 locations and feature dedicated Transair displays at our Ann Arbor and Shelby locations.”

Exotic’s Transair Product Managers are available to offer on-site demonstrations, training and assistance to customers. Additional information can be found at www.parker.com/transair.

About Exotic Automation & Supply: Exotic Automation & Supply’s headquarters is located in Farmington Hills, Michigan. The company maintains full service centers throughout Michigan & Indiana with locations in Freeland (Saginaw), Lansing, Taylor, Flint, Jackson, Noblesville, Rochester Hills, Shelby Township as well as at the main Farmington Hills complex.