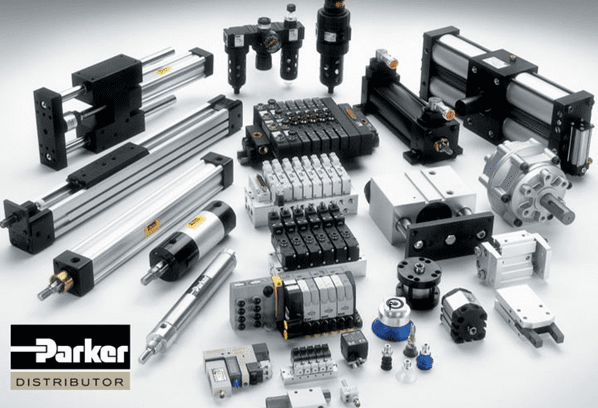

Pneumatic valves have come a long way since the development of the compressor more than a century ago and it can be a real challenge to ensure you’re taking full advantage of the latest development for your organization. Here are three ways to adopt the latest advances in pneumatic valve technology…

- Choose components that adhere to ISO valve standards

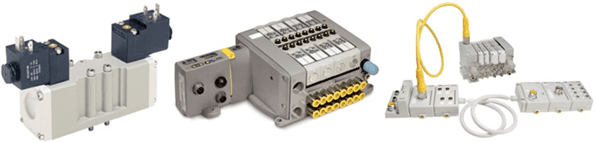

ISO International Standards ensure that products are safe, reliable and of good quality, helping to deliver increased customer satisfaction through consistent quality. ISO standards can also be used strategically by businesses to help reduce costs through improved systems and processes, minimize waste and increase productivity. - Opt for intelligent and simple wiring solutions

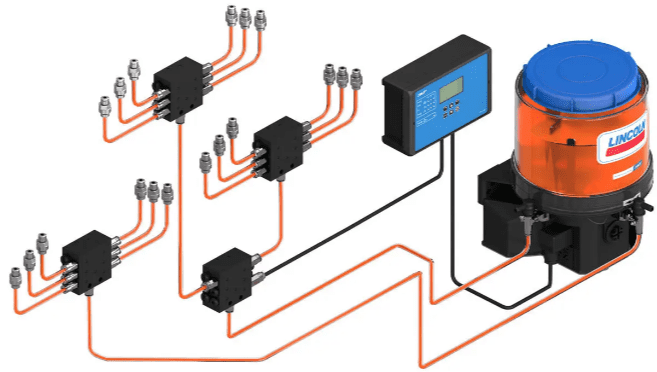

Utilizing collective wiring solutions provides and elegant mechanism to consolidate solenoid wiring into a single “collective” connection on the valve manifold. This method significantly reduces costs and complexity, as the valve can be moved out of the control cabinet to the point-of-use application located near the pneumatic process, eliminating long tubing runs and delayed responses in operation. - Incorporate cloud-connected innovations

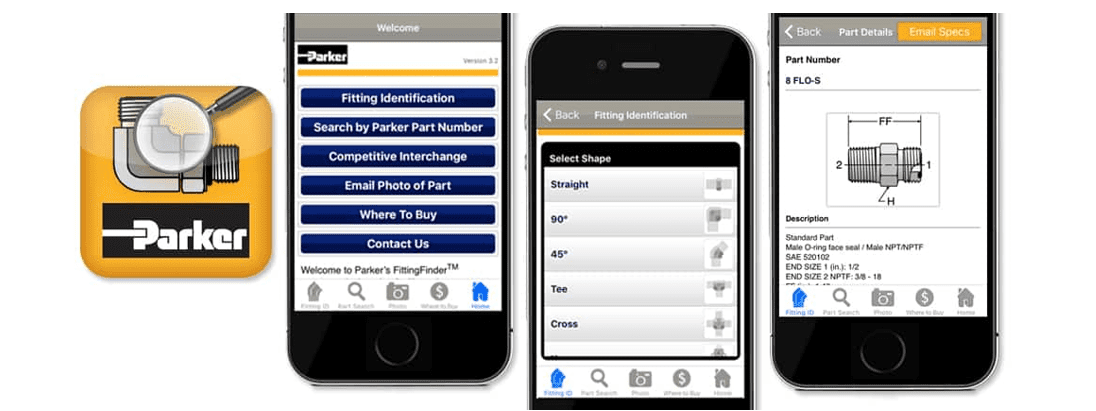

Incorporating a fieldbus solutions to control pneumatic valves could be the first step towards implementing intelligent, cloud-connected industry 4.0 innovations on the assembly line. These solutions create an automated industrial network, specifically designed for communications between programmable logic controls (PLCs) via a communications system such as Ethernet.