Challenge:

The customer was faced with an assembly request that required positioning of a product to a specific position prior to other parts being assembled. This assembly method was previously completed manually. As a result, the customer was faced with ergonomic issues due to manually have to actuate a pivot mechanism that holds some parts in place. In addition, they have been challenged with limited space on the fixture for other products.

Solution:

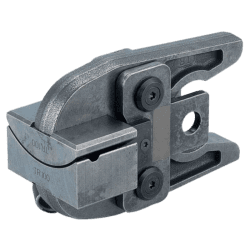

A model 331 pull action clamp was customized so that it actuates a pivot mechanism that correctly and consistently positions the product during assembly and holds the parts in place as others are installed.

Result:

Changing to the customized 331 clamp has resulted in a 20% increase in productivity and eliminated ergonomic issues.